|

CMOS MEMS Creating microstructures and MEMS in and out of CMOS materials (CMOS MEMS) is a unique technology that originated and continues to be developed at the MEMS Laboratory of Carnegie Mellon University in Pittsburgh, Pennsylvania. Devices being made with the CMOS-MEMS process include: x-y-z microstages for a probe-based mass-data-storage system on a chip, biologically inspired microsensors, ultrasonic sensor arrays, accelerometers and gyroscopes for an on-chip inertial measurement unit, and acoustic MEMS earphones.

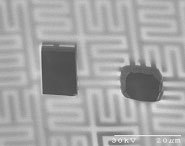

Acoustic CMOS MEMS Acoustic CMOS MEMS structures and devices are an extension of CMOS-MEMS that enables the fabrication of an integrated membrane or membrane arrays to be used either as sensing elements (microphones to measure sound) or as actuating elements (microspeakers to produce sound). To construct a membrane using CMOS-MEMS for either microphone or speaker applications, we make an airtight membrane on the surface of the chip by defining a mesh or screen-like structure and coating the mesh with a polymer to make it air-tight. The fabrication steps that create acoustic CMOS MEMS devices are described and illustrated below: |

|

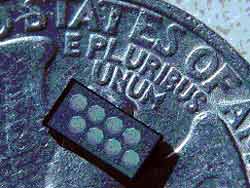

In addition to the simple fabrication sequence, the acoustic CMOS-MEMS devices have the advantage of integrated, on-chip electronics. For microphone applications, sensing circuitry (capacitive or piezoresistive) can be placed close to the mechanical structure, minimizing electromagnetic pickup and parasitic capacitance. For speaker applications, driver circuitry can be placed nearby the mechanical structures. In both microphone and speaker applications, signal processing electronics for signal conditioning (for example, noise cancellation and equalization) are also on-chip, increasing Akustica product performance, reliability and affordability. Demonstrated Devices Acoustic CMOS-MEMS enables Akustica to fabricate single and multiple membranes on standard and state-of-the-art computer and signal processing chips for revolutionary microphonic, speaker or combined microphonic-speaker applications addressing a variety of different markets. To date, acoustic CMOS MEMS have been used to fabricate single-membrane earphone speakers that are 2mm x 2mm square, a microphone less than 1 mm x 1mm and speaker arrays with up to eight (8) individually controllable speakers in an area about twice the area of the eagle head on a quarter. Below is a picture of a 2 mm x 2 mm microphone chip with a single membrane and integrated electronics. The 0.7 mm x 0.7 mm membrane is the dark blue area in the center with the associated and integrated electronics located beneath the green rectangles distributed about the perimeter of the chip.

The multi-membrane chip below is an array of eight membranes, each individually controllable and electrically isolated from the other membranes.

|

|

|

|||